Simply put, supercharging is any process that increases the amount of air intake to the engine.

Figure 1 - Turbocharger core

In automobiles, these two processes are often combined in supercharged systems, increasing intake pressure, and with an intercooler, reducing air temperature, increasing the air mass density and volumetric efficiency of the engine.

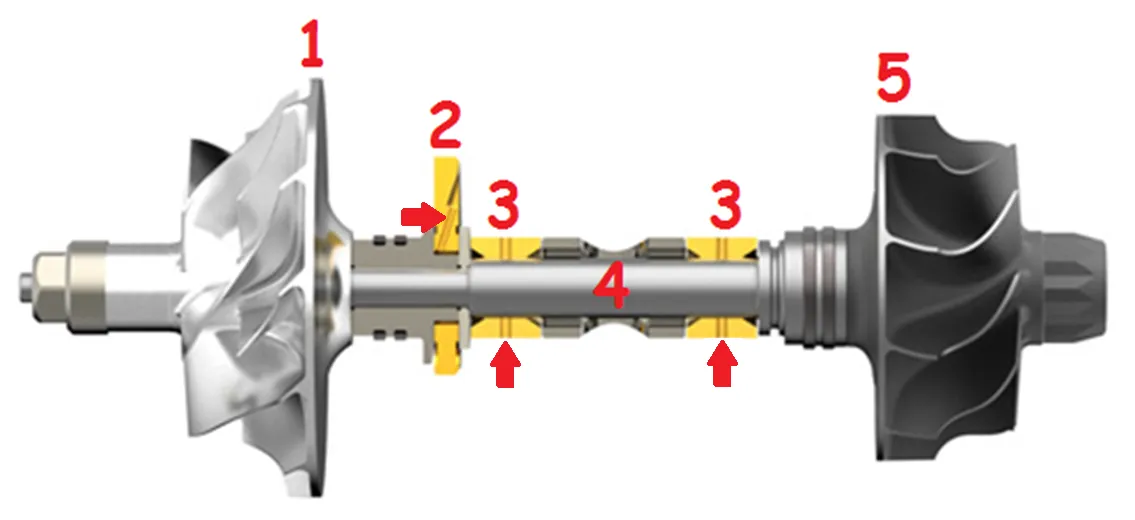

Figure 2 - Elements constituting the rotor

This element is of great importance for the component, as it houses various lubrication elements and the rotor, which consists of the compressor, turbine, and the respective shaft.

The rotor is shown schematically in Figure 2.

Maximize your engine's power and efficiency with LD Auto’s supercharging services. We specialize in turbocharger installation, maintenance, and repair, ensuring superior performance and more efficient driving.

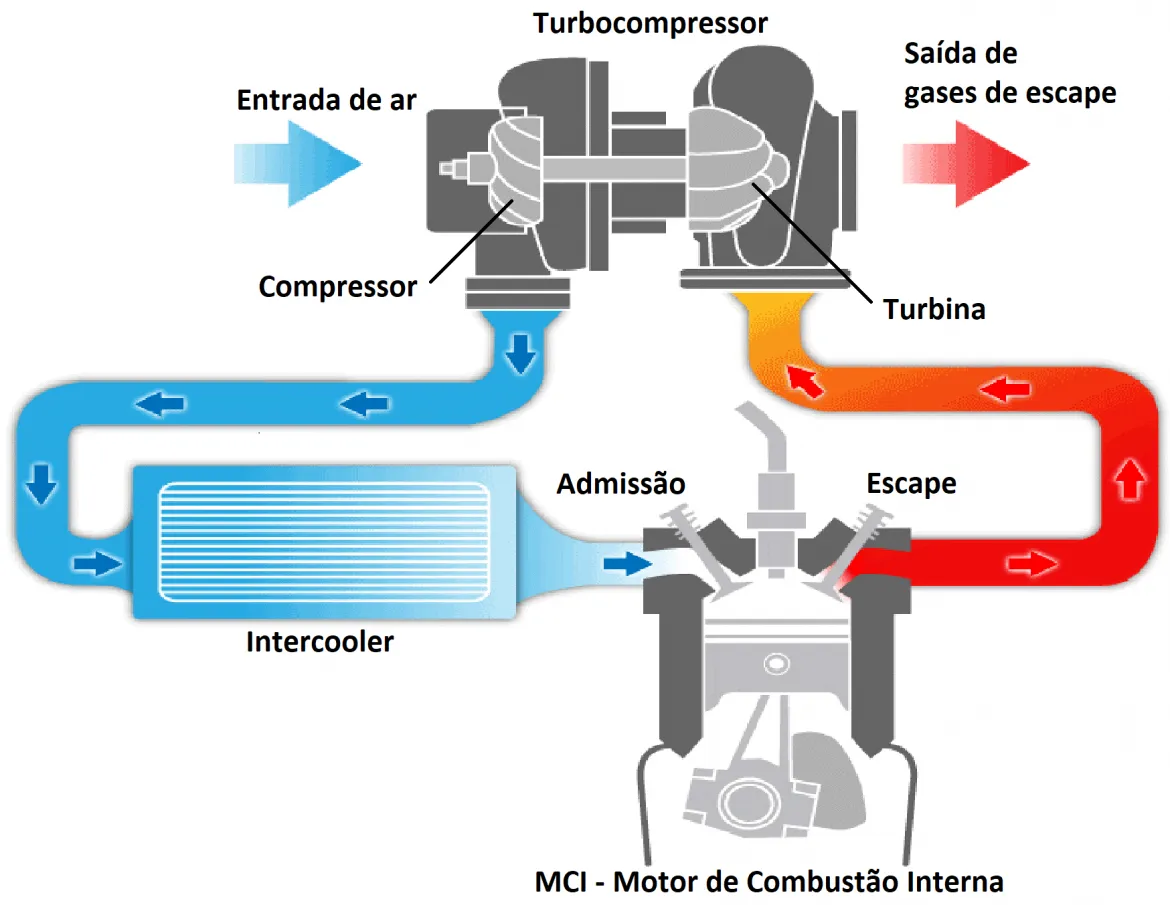

The operation of a conventional supercharged system is represented in Figure 3.

Both supercharging systems have the same goal: to increase the amount of air admitted into the engine to boost power and torque.

Increasing the intake air pressure allows more fuel to be burned in each engine cycle, resulting in an overall performance boost.

However, there are differences in how they are driven and implemented, with advantages and disadvantages associated with each system.

Figure 3 - Supercharged System

Within the ICE (Internal Combustion Engine), the combustion of the mixture (air and fuel) occurs, resulting in exhaust gases. The formed gases are then expelled to the exhaust, entering radially into the exhaust scroll of the turbocharger, driving the turbine, transferring motion to it, and then being expelled axially to the outside.

The turbine and shaft of the turbocharger are coupled together and then connected to the compressor. Therefore, the movement transferred from the exhaust gases to the turbine is also transmitted to the compressor, causing the entire rotor (see Figure 2) to rotate.

Before being admitted into the engine, the air enters axially into the intake scroll, where it is compressed by the compressor. The compression of the air causes an increase in pressure and temperature of the gas, which is then cooled in the intercooler and subsequently admitted into the engine.

Given the operation of a turbocharger, where energy is transferred from the exhaust gases to the rotor to increase the intake air pressure, the component is more efficient at higher engine speeds, starting from 2000 rpm. At lower engine speeds, the exhaust gases still do not have enough energy to increase the rotor speed, which can reach 300,000 rpm at high regimes.

Modern vehicles are becoming increasingly complex, and there is more and more interaction between the various systems in the vehicle. Therefore, the malfunctioning of one system can affect the performance of the others.

As explained earlier, a turbocharger allows more air to enter the engine, and with it, more fuel is injected, causing a significant increase in power in the ICE. However, the increase in power is not the only reason manufacturers use turbochargers. The component directly affects fuel consumption, allowing it to be reduced, lowers emission levels, influences the operation of the EGR valve, affects the performance of the particulate filter, and even impacts the operation of automatic gearboxes.

Optimize your engine’s power and efficiency with LD Auto’s specialized services. We guarantee reliable solutions for turbocharger installation and repair.

To ensure the correct functioning of the component and prolong its lifespan, it is crucial to carry out regular maintenance. Regarding this aspect, LD Auto recommends that the service be performed by specialized technicians and that all manufacturer guidelines and standards be followed.

The main failures in turbochargers are often caused by a lack of maintenance.

To extend the life of the turbocharger, the following should be observed:

Use of appropriate oil;

Short oil change intervals;

Replace the oil filter whenever recommended;

Check the oil pressure during interventions;

Maintain the air filter;

Keep the engine in good working condition.

No gasket or connection point should be replaced with glue or silicone as these products may contaminate or cause blockages in the system.

The most common failures in turbochargers are generally caused by a lack of vehicle maintenance or failures in adjacent systems affecting the component.

Wear of the turbocharger components leading to a displacement of the rotor on the horizontal shaft.

It is common to find damaged turbochargers due to foreign objects entering the system. Depending on the type of object, the damage to the turbocharger can vary.

There can be various causes for forced oil passage in a turbocharger, such as clogged oil return channels, defective engine operation with low compression, or defective injection.

In summary, the turbocharger is a crucial component for the proper functioning of the vehicle. Although it does not require direct maintenance, it depends on the maintenance and operating condition of the various systems adjacent to it, both upstream and downstream of the system.