The Car manufacturers More and more, they are opting to install automatic transmissions as standard equipment in new vehicles. The adoption by automobile manufacturers of automatic transmissions is mainly due to the reduction in fuel consumption and emissions of pollutants, as well as the ability of engines to produce increasingly higher torque, all of which is coupled with greater driving comfort.

CharacteristicsMain function of gearboxes: to gear down and distribute the engine's power and rotation to the wheels.

Possibility to obtain different ranges of torque and/or rotation.

Adaptation to driver requests and road conditions.

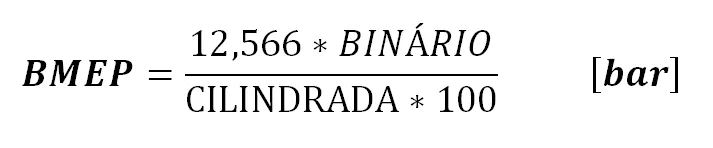

Through a transmission ratio, we can alter the output torque or rotation. This ratio is determined by the number of teeth on the gear pair, using the equation

For example, if we have an input gear (connected to the crankshaft) with 5 teeth, and an output gear connected to the differential shaft with 10 teeth, when calculating the transmission ratio, we will have a ratio of 2:1. This means that for every revolution of the input gear, the output gear gives 2 revolutions, resulting in an increase in rotation.

On the other hand, if we have one gear with 10 teeth and another with 20 teeth, then our ratio is 0.5:1, meaning that for every revolution of the input shaft, the output shaft doesn't complete one full revolution. In this case, we have a ratio that serves to multiply the torque to be transmitted to the wheels.

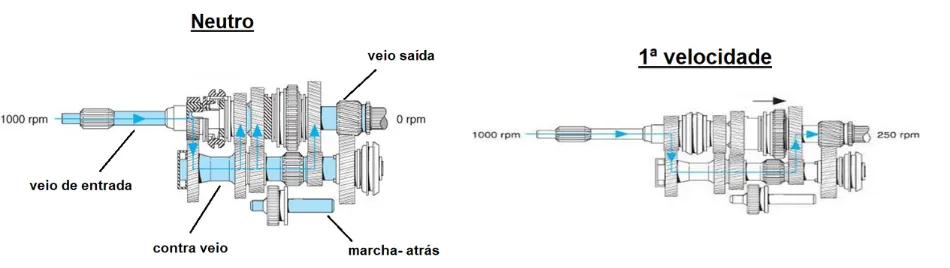

Figure 1 shows an example of how a manual in its neutral positions and with the first gear engaged. In the example we can observe the flow of transmission and when applying a rotation to the input shaft of 1000 rpm in first speed, at exit we have a gear ratio of 250 rpm. Or that is, we have a force relationship, since the input rotation (coming from the engine) is reduced to a quarter at the exit to the differential or wheels.

Figure 1 - Power Flow.

There are numerous solutions on the market in terms of gearboxes. both for light vehicles and heavy vehicles, divided into 3 categories.

Manual gearboxes

Piloted/robotic gearbox

Automatic gearboxes

Most vehicles are still equipped with gearboxes. manual speed. These boxes have a simple and effective, with relatively few components compared to boxes automatic, which makes them easier and more economical to manufacture. Yours constitution does not differ much from the first gearboxes developed and are roughly composed of input and output shafts. output, gear pairs, synchronizer washers, sleeves, forks or forks and a conical group (differential).

Automatic boxes, on the other hand, have many more components internal, compared to manual gearboxes. These are boxes that present a different and more complex construction, which makes them more difficult to produce and consequently more expensive to acquire. On the other hand, they are normally boxes in which mounting on the vehicle is usually faster and simpler. Depending on the year of manufacture of the box, are made up mainly of epicyclic trains, discs of clutch, metal discs, pistons, filters, belts, oil pump, valve group and torque converter.

A variant of gearboxes automatics are CVTs – “Continuously Variable Transmission”. O operating principle is based on power transmission via via a chain or belt.

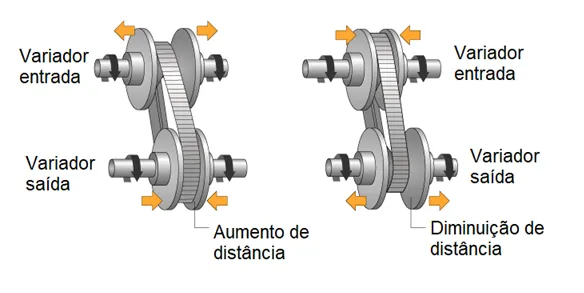

The transmission ratios from lowest to highest, are controlled by increments and decrements continuously through the variators (figure 1). Thus, in theory these boxes have multiple cash ratios that as the rotation increases, it causes the so-called “shift of box” is practically not felt.

Figure 2 - Variation of the transmission ratio in a box of this type CVT

Between manual and automatic gearboxes, we have piloted gearboxes or robotic. This type of gearbox is characterized by being a mix of manual gearbox type with automatic control. In terms practical, this type of box has all the components associated with a manual gearbox (gears, synchronizers, forks, etc.) but with a robotic part that manages and controls cash flow, read speeds. This action is typically carried out in a electro-hydraulic.

Currently automatic gearboxes are based on their operating under hydraulic oil pressure, and are controlled electronically with the increasing adoption of control units box incorporated inside it.

Regardless of the type of box, they all have one thing in common: lubrication.

LubricationLubrication in gearboxes, and especially in gearboxes automatics, as with engines, is fundamental for good functioning of the entire system.

Poor or non-existent maintenance of the gear box automatic, leads to numerous problems, which then affect the group of valves, converters, pistons, clutches, etc.

Also the use of the correct lubricant, which meets the standards of the manufacturer, reduces the possibility of some types of faults or complaints on the part of the driver.

For example, the use of an automatic gearbox lubricant specification lower than recommended may result in operating times box performance are not correct. This is due to the different oil viscosities. The most common lubricant in boxes Automatic speed is ATF. Although many times the ATF lubricant be all similar, in reality this is very different, as a result of their technological evolution. One gearbox automatic is factory-set to a specific oil that meets certain characteristics, including What is the cash flow time? If the oil has a viscosity different from that recommended, the cash flow time is changed This could result in various problems and complaints.

Despite the fact that in recent years many manufacturers claim that the boxes newer models do not require maintenance, LDauto technicians have come to realize that they benefit from changing the oil and filter, thus avoiding premature wear and other problems.

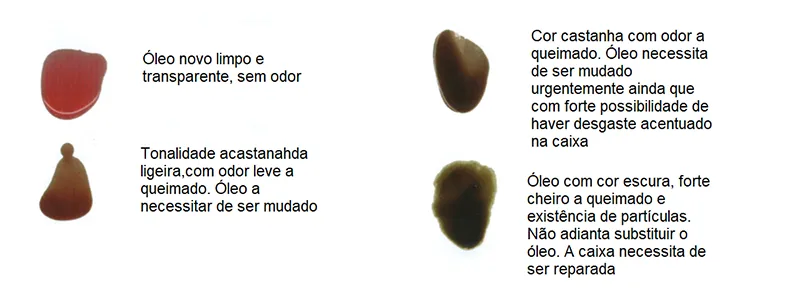

In image 2 we can see the evolution of the lubricant degradation of the ATF type of an automatic gearbox.

Figure 3 - Condition of the lubricant gearbox throughout its operation

On the left the lubricant is shown in its new state and running to the right you can observe the degradation throughout the use of the box.

When the oil condition reaches the maximum saturation point, it loses its lubricating properties, becoming less viscous, which will affect the operation of the valve group, for example.

Another problem that can arise from not changing the lubricant is the clogging of the box filter with particles/swarf resulting from degradation of the box oil.

In this way, LDAuto – Leiridiesel recommends maintenance preventive transmission of the box approximately every 60,000km with replacement of indicated box oil and respective filter. LDAuto has certified technicians and specific equipment for replacement of gearbox oil, using the dialysis method.